TechVan RD COVID Test and Vaccination Station

The Core Vehicle

The TechVan RD (Remote Deployment) is typically built upon an extended RAM ProMaster platform – one of the most reliable and highly rated commercial vehicles of its type. The ProMaster was selected for its reliability, its best-in-class cargo capacity, it’s class leading horsepower, and it’s safety features which include seven airbags (including driver and passenger airbags, the driver knee-bolster airbag, front seat-mounted side airbags, and front side curtain airbags), and12-inch front disc brakes which offer outstanding durability and impressive performance. Of course, this configuration can also be fitted to other comparable vehicles (Mercedes, Ford, etc.).

Other standard features include a rear backup camera utilizing advanced technology. The standard Uconnect 3 system features a 5” touchscreen with integrated Voice Command, Hands-Free calling, Bluetooth Streaming Audio, and convenient steering wheel controls. With a 12-volt outlet and high-speed USB outlet in the front and auxiliary 12-volt outlet in the rear, you can stay powered and stay connected.

It features a 3 year/36,000-mile basic limited warranty and a 5 year/60,000-mile drivetrain limited warranty.

Vaccine and PPE Storage and Access

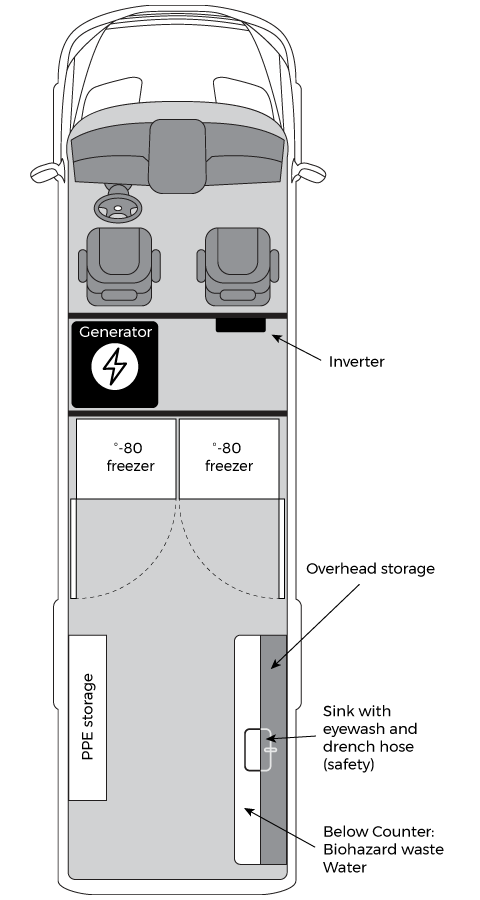

The TechVan RD Vaccination Station includes two 3.3 cu. Ft. -80-degree freezer, for maintaining the COVID vaccine in accordance with manufacturer’s recommendations. Each freezer operates for up to two + days without power using the unique power source described below. The configuration can be modified to include a -20 freezer, a pharmaceutical refrigerator, or any combination of the above.

Because the TechVan RD is designed for remote deployment where access to water may be difficult, we’ve incorporated a water storage tank with electric pump to a lab faucet and safety eyewash both of which are located at the sink draining to a contained waste vessel. This provides the ability to wash ones hands and clean materials that are potentially contaminated. The waste vessel is designed to contain the effluent from the sink until it can be disposed of in a safe and effective manner. Adjacent to the sink is additional counter space, with a biohazard containment vessel beneath. Access to the biohazard vessel is through the countertop. Above the bench and on the opposite wall are cabinets for storage of Personal Protective Equipment (PPE).

The Tech2 Advanced Power Source Technology

A critical component in the TechVan RD Vaccination Stations is the renewable power source for -80 Freezers mounted inside the vehicle. The reliability of this system is paramount to protecting the integrity of the vaccine and the successful distribution of an effective vaccination program.

Our Tech2 system consists of two independent 300AH lithium-ion phosphate battery for storage of 12VDC designed to continuously provide 120VAC at 60Hz and 3.3A or max of 600Watts feeding a 700-watt 120V sine wave inverter to power a single -80C freezer. The two sources serve as redundant backups to one another – an important consideration in remote deployment.

These batteries were selected because they do not produce gas when charging – all other battery types (AGM, sealed, lead Acid) produce hydrogen gas when charged. This gas can potentially lead to an explosion which requires that the batteries be separate from any electronics and have adequate ventilation. Further, these batteries last much longer than other batteries (10-year lifetime) and can be charged more often (2000-5000 cycles). The power supply we utilize includes a battery management system – so the battery is charged properly and safely and continuously monitored. Finally, this is the most environmentally friendly battery produced – nonpolluting.

The battery housings contain an automatically controlled 12VDC fan and intake built into the enclosure to keep the battery and electronics cool while in operation.

The Tech2 control system features a 4” color touchscreen with graphic user controls and status and utilizes a dual input charger/controller and inverter with 120V auto detection. Status display is via a battery monitor display and status lights for the 120V output. The display provides percent charged, time left, and battery voltage readout.

In addition to the capabilities provided in our Tech1 system, Tech2 controls provide the following:

- Auto–generator start to close a contact to automatically start a generator if the vehicle charging system is off and the battery charge gets below a programmable limit, AND to automatically shut off the generator once battery is charged.

- Auto Vehicle start would modify a vehicle key fob to charge the system – this would automatically start the vehicle if the charge level of the battery reaches below a programmable limit and automatically turn off the vehicle once the battery is charged.

- Solar charging option – simply activate and plug in the optional 210W solar cell – this in most case would keep the battery charged indefinitely as long as there is sun every few days. With approx. 1 hour of full sunlight the panel would charge the battery for about 5 hours of runtime.

The system also provides a separate 120V outlet onboard for use with ancillary equipment.

Safety/Disinfection

As the TechVan RD Vaccination Station is designed to be used for viral vaccinations, it is possible that contamination from PPE or other sources could be a risk. In order to mitigate the risk, the TechVan rear workspace has been developed to be effectively isolated* from the driver/passenger compartment and is designed rinsed down and/or disinfected.

Used PPE and other disposable materials can be collected and disposed of in a concealed biohazard containment vessel which can be removed and disposed of in a safe and appropriate manner (following guidelines recommended by health officials and established as part of the vehicle Standard Operating Procedures).

To ensure that no trace contaminants are active, a special UV light is provided which automatically cycles on for 5 minutes whenever the vehicle is started. We also offer an option for ozone disinfection.

Finally, to further minimize exposure risk, the optional rinse down system routes effluent to collection via the drain/collection system incorporated into the underside of the vehicle and disposed of in a safe and proper manner (as determined by owner Standard Operating Procedures and recommendations of health officials). With this option, all interior components (wall and floor surfaces, PPE cabinetry, power supply housing, freezer housing, etc.) feature sealed access and are designed for rinse down without damage to contained materials.

*Note that complete isolation of the space is impossible due to the nature of construction of the core vehicle, but every reasonable effort has been made to minimize any risk of cross contamination from one space to another.

Additional Pertinent Features

The modular design of each component within the Vaccination Station allows for simple/cost effective replacement should the need arise. Although we have chosen the most reliable components and design, we are realistic in acknowledging that things sometimes fail. We have designed the Tech/Van RD Vaccination Station to be prepared for the unexpected by allowing for modular interchange of components.

The TechVan RD Vaccination Station is fully wrapped in high-quality 3M vinyl wrap with professional graphics identifying it as an official Test and Vaccination Station. In addition to providing a high profile for the pandemic vaccination program, we believe this designation provides a level of safety to occupants when delivering vaccine.

Thinking Ahead - Repurposing the Vehicle

The COVID pandemic vaccination program won’t last forever. There will come a day when you may want to repurpose the vehicle. We’ll be there. The RD Vaccination Station is only one of many configurations possible for the TechVan RD. We can assist you in repurposing to a design of our own or to your own special application. The interior is designed and constructed such that reconfiguring can be accomplished with minimal effort. The modular design of each component ensures that removal and replacement are easily accomplished. Even the exterior is easily changed as the chosen wrap materials are uniquely able to be removed should the van be repurposed.